What is Mold and Molding?

Mold is a very important part of the manufacturing process of any product.

With the mission of taking technology as guideline for development, we always research and change to meet all customer’s requirements about mold production.

- Description

Description

Learn about Mold

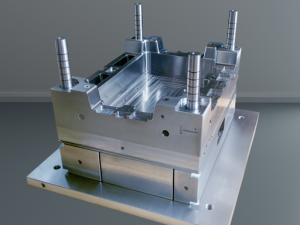

A mold is a metal tool (equipment) used to shape products according to the profiling method. This product is typically made and used for a certain number of molding/pressing cycles, which can be one-time or multiple. The texture and size of the mold depends on the size, shape, quality and quantity of the required product.

Types of popular molds today

Injection molds are widely used in industry to make parts from various materials such as plastic, metal, rubber, glass, etc. and other inorganic substances. Products from injection mold include metal and plastic parts in automobiles, airplanes, home appliances, electrical appliances, electronics, consumer goods, furniture, military equipment, medical products.

The molds used in the production of plastic products include many types as below:

- Injection Molding

- Compression mold

- Blow mold

- Reinforcement mold

- Moving mold

- Casting

- Extrusion mold

- Rotational mold

The most popular is injection molding.

Stamping dies are used to manufacture a wide variety of metal products, using methods such as stamping, extrusion, forging, drawing. Stamping products are widely used in the manufacture of automobiles, aircraft, furniture, construction equipment, agricultural machinery, household products, electronic products, and many other types of products.

Mold production process

Like mechanical products in general, the mold manufacturing process is based on the main technological process including: Design, machining, heat treatment, testing and assembly. A company can take responsibility for one or more processes, even the whole production process to make the final product.

In the same closed cycle from order receipt, analysis, processing, delivery and implementing repair and replacement of mold components, Vietnamese mechanical companies participate in all stages.

The mold is a single production product, which makes the mold product unaffected by economies of scale. This is an advantage for Vietnam to be able to compete with other countries, especially China. The mold market in Vietnam as well as in the world is growing at a high speed and has a significant capacity. Vietnam’s technology level in this industry is not too low and is likely to develop to catch up with the world average.

Contact us the get the best price!

Bình luận (Comments)