JIG Mold in Machining

- Description

Description

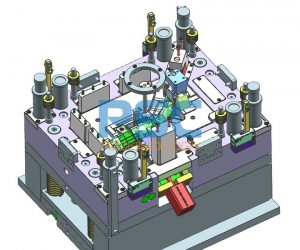

1. What is Mold Jig?

Jig molds, also known as jigs, are used to attach parts or assemblies. This is an auxiliary device used for fixing and assembling and testing products. In addition, it also determines the necessary position of the workpiece to hold the workpiece tightly during cutting and machining to ensure high accuracy.

2. Uses of Jig mold

- Fix the details, help not to move the product, ensure the positions between the workpieces together.

- Determine the positions of workpieces on the machine quickly and accurately.

- Create movements for machining complex surfaces.

- Reduce production time, improve product quality.

- Reduce direct workers in the production process.

- Bring high-precision products, manufacture large quantities, increase product quality.

- Improve the ability to produce highly complex parts.

3. What types of Jig Molds are there?

Jig molds are classified by use, including 6 basic types: welding jigs, assembly jigs, inspection jigs, compression jigs, milling jigs and roughness gauge jigs.

3.1. Welding Jig Mold

Welding jigs are processing equipment for welding parts with complex structures and shapes. The large tie bar keeps the welding fixture stable in the face of pressure, heat, movement and force. Combined with clamping function to improve accuracy and safety during machining.

3.2. Assembly Jig mold

Assembly jigs are used when it is necessary to assemble complex parts together. Both meet the technical requirements and shorten the machining time.

Assembly jigs contribute a lot in stages such as clamping workpieces during assembly; making jigs and holding parts for assembly; deform the details to serve the welding, pressing products, …

3.3. Test Jig mold

Test Jigs are used for checking specifications, from the start of production to the end. The jig holds the product in place, preventing it from being moved or vibrated by external forces to help the engineer measure the detailed thickness, check the dimensions, etc. Thereby ensuring that the finished products are manufactured in compliance with the technical requirements and drawings.

3.4. Compression Jig mold

Compression Jig is used to fix material parts before welding or assembly. It replaces the worker to keep the part firmly and stably for a safer and faster machining process.

3.5. Milling Jig mold

Milling Jigs are used to position material details to perform machining processes on CNC milling machines. Because the cutting force generated is quite large, the structure of the milling fixture must also be large enough to ensure that the product does not move or overturn.

3.6. Roughness gauge Jig mold

Roughness gauge jigs are used to check the surface roughness of parts and products in a short time. Enterprises can save maximum human resouces and detect substandard surface quickly for reprocessing.

4. Notice to choose Jig mold

- When designing and choosing jigs, pay attention to the following factors:

- Position, strong clamping ability, fixture accuracy

- Simple structure, easy to use, replace and combine with other product.

- Jigs need to ensure quality andconvenience for fixing products in the production process.

- High durability, resistant to cutting forces, not damaged during use.

- Safe for users and operations.

- Design with high aesthetics.

Bình luận (Comments)