Plastic Injection Mold and Things that you might not know

- Description

Description

Learn about plastic molding

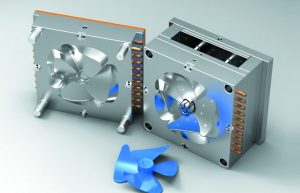

Plastic injection mold is one of the equipment used in the injection molding process. The design process is extremely complex to be able to meet the needs of users.

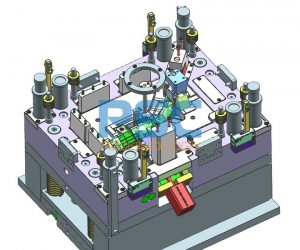

Parts of plastic molding

Parts of this product are typically fabricated using one of two methods: standard & CNC machining and EDM discharge machining.

Standard machining

Somes types of machines commonly used to make standard plastic molds include: lathe, drill and milling-machine. As technology has become more and more advanced, CNC machining has become the main way used to create complex molds with high precision.

Electrodischarge machining (EDM)

Electrodischarge machining (EDM) is widely used in mold making. Through the use of electrodes made from graphite or copper, the desired shape is obtained.

When two electrodes are brought close to each other, an electric field exists between them. When the voltage is increased, electrons are ejected from the cathode surface, continuing to increase the voltage, the dielectric between the two electrodes is ionized to be conductive and cause sparks between the two electrodes. The temperature in the spark area is very high, up to 12,000 degrees Celsius. This temperature melts and burns the metal on the anode. During the discharge process, a strong ionization occurs and creates a huge impact pressure, pushing the workpiece out of the machining area.

Another advantage is that it allows prefabricated molds to be formed and eliminates the need for additional heat treatment.

Some common Materials used to make Plastic Mold

- Pre-hardened Steel (one type of steel)

This steel has a balance between strength and formability. Pre-hardened Steel is strong enough to withstand abrasion in high volume product production. More over, it is also ductile enough to undergo forming from milling and machining or other standard tools. Pre-hardened Steel molds are capable of making production cycles of hundreds, of thousands of parts.

- Hardened Steel

Hardened Steel molds are designed for long-term and high-volume production operations. They are the strongest and most expensive injection molds. Making Hardened Steel plastic molds is more expensive due to the heat treatment that occurs in the the fabrication process. After hardening, less common forming methods, such as EDM cutting, must be used to form the mold. Hardened Steel is highly resistant to abrasion and molds made of this material are capable of participating in the production of millions of products.

- Aluminum

Aluminum is a relatively inexpensive forming material, suitable for injection molds performing low-volume production or prototyping. The malleability of aluminum makes it easier to make plastic molds. However, the resistance of aluminum is quite low, which reducing the life and abrasion resistance of the molds, making them unsuitable for long-term projects.

Plastic mold design

Plastic mold design is an extremely important stage, directly affecting the operability and accuracy of the mold. To design a plastic injection mold, it is necessary to have complete information about the product and the injection method.

Properties of materials used in plastic products

- Shrinkage of plastic

- Purpose of product

- Length of time for the injection molding cycle

- The need to engrave patterns or logos on the mold

- Assembly tolerances between products (if any)

- The appropriate mold exit angle

- Suitable type of channel system (cold channel, hot channel or both)

- Nozzle position, flow, product welding line

- Nozzle size and type

- Parameters of injection molding machine: nozzle size/ size/ plasticizing capacity

- Machine automation

- Mold completion time

- Cost and price

Above is the basic information PSCTECH shares about plastic molding. Hopefully, the article will bring useful knowledge to you.

PSC IT ., JSC has many years of experience in the field of mechanical engineering as well as standard mold making. We provide main products such as: Mold, machining, composite and design services. With a team of experienced and professional design engineers. The company always not only updates and apply but also improve technology to produce high quality products. We have been cooperating with many partners, large and small, and have received trust and confidence from customers.

Contact Info: https://psctech.vn/

Hotline/ zalo: 0914869163

Facebook: https://www.facebook.com/PSCTECHVIETNAM

Bình luận (Comments)