Aluminium Die Casting Products

- Description

Description

Basic information about aluminum die casting products

Aluminum is a common input material used to make products for many industries.

For example:

Aluminum used for sheet metal processing will exist in sheet form.

Aluminum used for pressure casting processing will be melted and put into a mold similar to plastic injection molding.

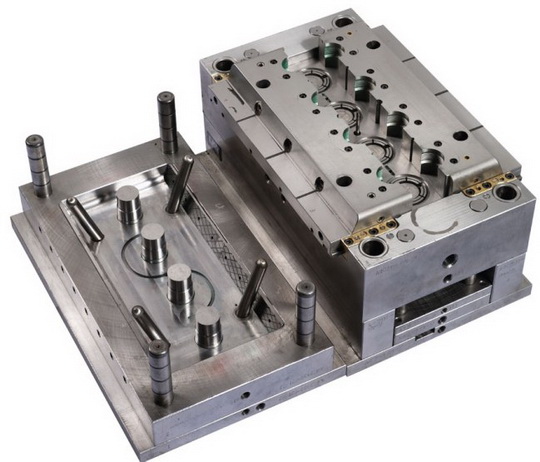

The machinery manufacturing industry needs a lot of aluminum products that are machined by aluminum pressure casting. Aluminum die-casting mold is the tool that forms the required industrial machine parts and details.

Aluminum is cast from high-precision molds: no warping, no surface cracking, and having the ability to produce thicker parts than pressure stamping.

The more precisely the aluminum die is designed, the more perfect the aluminum-casting product will be. The shape and quality of the mold is directly proportional to the quality of the molded product.

The advantages of aluminum die casting

- Die casting aluminum is the ideal solution for dealing with parts and components with complex shapes and demanding tolerances.

- It allows capability of casting diverse materials: aluminum, aluminum alloy.

- Create more cost-effectiveness than aluminum casting methods by sand mold, melt mold.

- High use value, long mold life.

- Molds for the production of aluminum metal parts enable high precision products, smooth surfaces, and solid textures.

- Fast forming processing time. Liquid aluminum is injected into the mold cavity under high pressure, and then cooled, the liquid aluminum will solidify. The finished product is free from burrs, has no surface pitting, no cracks, etc. The aluminum die casting process is easy to produce continuously and stably.

PSC TI ., JSC has the capacity, technology to design and manufacture aluminum die-casting molds as well as standard mold manufacturing. We provide main products such as Mold, machining, composite, and design services.

Bình luận (Comments)